Mining is changing – and data is at the heart of this transformation. Powered by advanced computer vision, MineView AI transforms existing video streams into real-time, actionable insights that prevent risks, optimize workflows, and protect your workforce. Designed specifically for the demanding conditions of mining, MineView AI enhances productivity, increases operational transparency, and ensures a safer, smarter future for your mine.

Every day, mining operations generate enormous amounts of data. Cameras, sensors, and monitoring systems capture everything from drilling progress to conveyor belt performance. Yet much of this data remains underutilized, requiring manual inspection and leaving blind spots.

Artificial intelligence changes this. By detecting patterns and deviations in real time, AI allows mines to:

- Identify hazards earlier

- Optimize processes automatically

- Reduce downtime and operational costs

AI doesn’t just analyze data – it transforms it into knowledge that makes mining safer, smarter, and more sustainable.

The Solution: MineView AI

MineView AI brings visual intelligence directly to your mining environment. The system builds on your existing camera infrastructure – no costly new investments required – and scales easily across operations.

With MineView AI you gain:

- Continuous real-time analysis of video data

- Seamless integration with current systems and workflows

- Immediate alerts when anomalies or safety risks are detected

- Full control and ownership of your data

Drill Monitoring

Unplanned drill bit failures and idle times cost valuable production hours. MineView AI monitors drill activity and bit condition continuously, providing early warnings of wear, inefficiencies, or deviations. This reduces downtime, improves equipment life, and helps operators benchmark and optimize drilling performance.

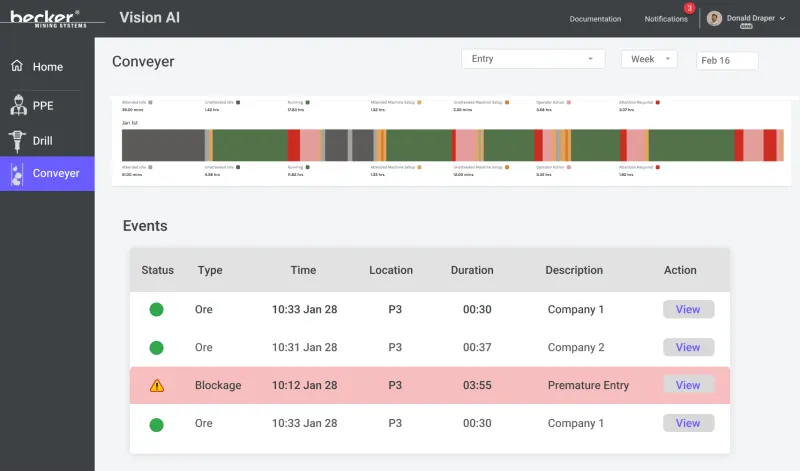

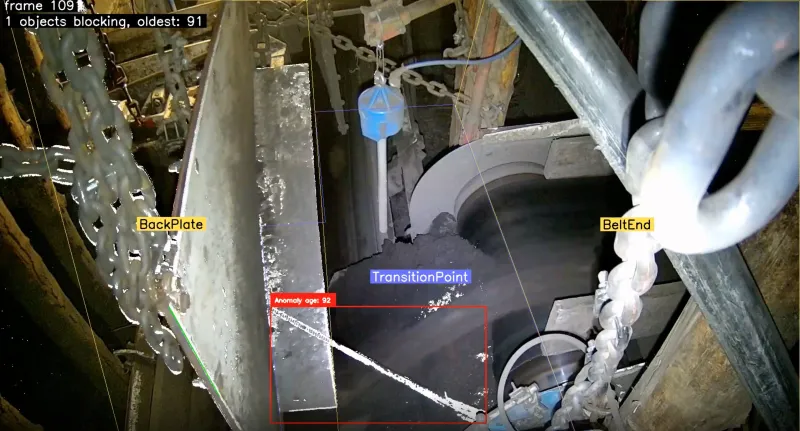

Conveyor Belt Monitoring

Conveyor systems are the backbone of material transport – but also a common source of costly breakdowns. MineView AI tracks belts for tears, blockages, misalignments, and abnormal vibrations. Real-time alerts enable maintenance teams to act before small issues escalate into major stoppages.

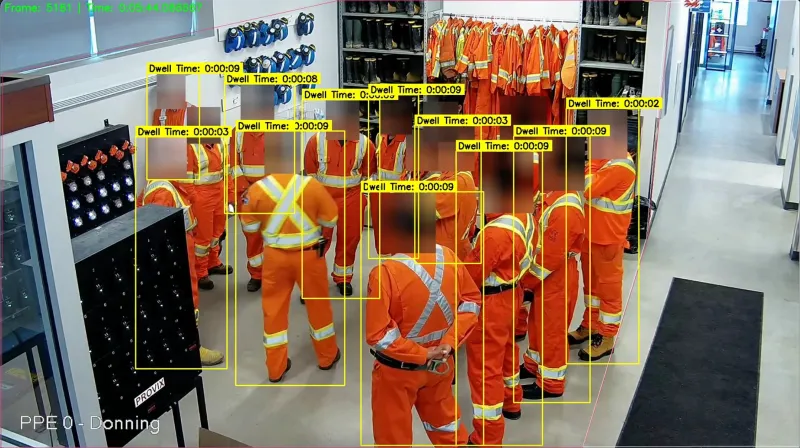

PPE Detection

Safety begins with the right personal protective equipment. MineView AI automatically verifies compliance with PPE requirements, such as helmets, hi-vis clothing, or gloves, and immediately alerts supervisors to violations. This ensures worker safety, reduces risk of incidents, and simplifies regulatory compliance.

FAQ - Detailed Version

All you need to provide is video. Becker Mining Systems will convert the raw, unstructured footage into powerful AI models and applications – simple and hassle-free.

Our MineView AI system works with most existing camera infrastructure. In some cases, repositioning or adding cameras may be necessary to ensure full coverage. If you don’t have cameras installed, we can help you source hardware with the right specifications.

The required processing hardware depends on your specific setup. Typically, we use AI edge devices like NVIDIA Jetson or local servers when handling multiple camera feeds. For cloud-based solutions, only a computer capable of transmitting video is needed on-site.

Yes – MineView AI is designed to work with what you already have. It’s not a rip-and-replace solution.

No, but we provide detailed specifications and can connect you with trusted hardware partners.

Our MineView AI is edge-first by default – this reduces bandwidth requirements, cuts latency, and enables real-time processing. If needed and feasible, we also support cloud-based processing.

We take data privacy and security seriously. All data is encrypted at rest and in transit, with access limited through role-based permissions. We apply anonymization techniques like face-blurring as required, and we are fully compliant with GDPR and other data regulations. Our goal is to protect privacy, ensure integrity, and build trust through transparent data handling.

During development, video is stored and processed. Once the application is running, storage is optional and based on your preferences. Data can be retained for performance validation if needed.

You do. The customer always retains ownership of their data.

Yes, we comply fully with GDPR, CCPA and similar frameworks.

We use computer vision to blur or redact personal features like faces, depending on regulatory or client-specific requirements.

Every MineView AI solution is adapted to your specific environment. We fine-tune models and adjust business logic for your use case. If you need a new feature or application, we can develop custom solutions in close collaboration with you.

Yes – we offer flexible APIs and work with your teams to build what’s needed.

Yes, as long as we receive updated video from the new environment for training and validation.

The system can handle many changes, but to maintain performance, we recommend collecting new data from the updated layout.

You’ll receive ongoing support for both software and hardware. We provide updates for our computer vision models and manage remote deployments when needed. Maintenance is part of our commitment to long-term success.

Yes – we provide detailed analytics, insights, and proactive support to ensure ongoing value.

We collect and process new data, retrain the models, and deploy the updated version remotely to your site.

No – our expert team manages the process for you to ensure the best performance and reliability.

We use a robust test framework to compare model predictions against ground-truth data from your environment. This process is carried out during the pilot phase and periodically after deployment to ensure accuracy and consistent performance.